How to choose a suitable Paller Wrap Stretch Film

In this article, we would like to help you understand the range of Pallet Wrap Stretch Films with a width of 500 mm (= 19.685 inches), what the individual data mean and what parameters to focus on.

Film thickness:

The film thickness is given in millimetres (mm) or micrometres – microns (µm) for short. 1 micron (µm) = 0.001 mm = approx 4 (3.937) gauge (ga).

The most commonly used stretch film for pallet wrapping has a thickness of 23 µm = 0.023 mm, which provides sufficient fixation for all common types of palletised goods, even for tall pallets.

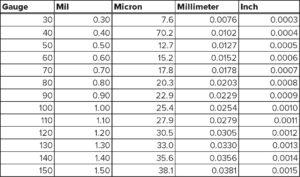

Image: Illustrative overview of the use of stretch films of different thicknesses

The thicker the film, the better it fixes the goods during transport and the more resistant it is to tearing. At the same time, the thicker the film, the more expensive the pallet wrap itself is, as more packaging material is consumed. This also generates more waste when the pallet is unwrapped, leading to the need for more frequent removal of waste containers and a higher negative impact on the environment.

Therefore, we recommend you to use lower thickness films when packing pallets with lighter goods, which will ensure sufficient fixation during handling and transport, and at the same time help you save an interesting amount of money for packing goods, as well as improve the environmental impact. Therefore, in our offer you will find economical variants of stretch film with thicknesses of 20, 17, 15, but also 12 microns.

Image: Comparison of waste rates of different thicknesses of stretch film when wrapping an identical pallet (with the same length x width x height specification)

Length:

Length is a key factor in the profitability of a purchase. The length determines how many metres of film are wound on one roll. The greater the length, the more pallets you can wrap with one roll of stretch film. Most of our stretch films are wound on a lightweight 240g core (tube). This allows us to wind a larger amount of stretch film per roll than a standard 680g core while maintaining the same overall roll weight (an important factor when handling film). At first glance, the purchase price of a roll with a lightweight core is higher than that of a roll with a standard tube (680g), but after recalculating the price per metre of film, a roll with a lightweight core is more cost-effective. Another advantage of the lightweight tube roll is that, when packing many pallets, there is no need to replace the roll frequently, and fewer kilograms of waste from unnecessary tubes remain after the entire film has been used up.

Figure: Comparison of stretch film lengths with different core weights at the same total roll weight

Our coreless stretch films are the leader in this respect. These films offer the same packaging properties as conventional stretch films on tubes, but at the same time they bring a number of advantages: the weight of the roll corresponds to the net weight of the film, you don’t have to worry about disposing of paper tubes, and by using them you significantly reduce your environmental impact. Simply purchase a one-off unwind for the coreless stretch film and then work with the roll in the same way as with a paper core.

Weight of the roll:

The total weight of the roll is the sum of the weight of the paper tube and the film itself. The lower the weight of the tube, the larger the roll of stretch film per roll of the same weight.

Stretch film for manual pallet wrapping is available in weights from 1 kg (= 2.205 lb) to 3 kg (=6.614 lb). A compromise between ease of handling and cost-effectiveness is the 2kg (=4.409 lb) stretch film. For easier handling, we recommend choosing a roll with a lower total weight. If you are looking for a cost-effective film, and at the same time the higher roll weight is not a problem for your employees, we recommend choosing the 3kg variant.