We offer layered PE films, which are characterized by significantly higher strength and durability

… thanks to this, your products can be wrapped with a lower thickness film while maintaining the existing wrap properties.

Polyethylene (PE) films are the most widely used material option for group and palletisation packaging.

PE is most commonly supplied as LDPE (Low Density PolyEthylene), which, due to its „softer“ structure, has suitable properties for the packaging needs of most types of products. If it is necessary to change film properties such as strength, flexibility and slip resistance, additives are added to the film.

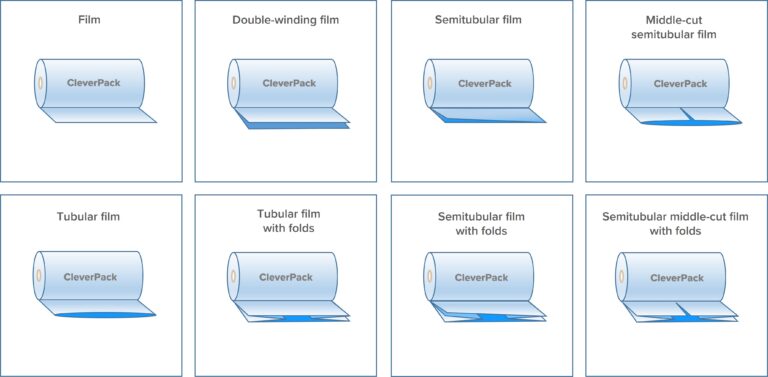

Form of supplied films:

Flat, hose and semi-hose with folds

- packaging of bottles, canisters, bulk materials, boxes, etc.

Palletising bags / hoods

- pallet packaging in the form of an overlay, or as a stabilization of goods for transport

Cover sheets, cut-to-size sheets

- covering the top of the pallet, or as an interlayer film

Bags & sacks

- unlimited use for packing small materials or as large waste bags

Use of LDPE films

HEAT-SHRINKABLE

- heat shrink, group packaging any products, palletizing bags

STANDARD

- slightly shrinkable

- used primarily as covering and interlayer film

RECYCLED

- honey colour, technical – clear, recycled residues from production

- same use as standard

Adjustments of films

All films can also be further modified.

Possible tretaments:

- UV stabilization 6 to 60 months

- antistatic treatment

- anti-corrosion protection (VCI)

- treatment for direct contact with food.

- layering (Coex) – offer of 1-layer to 5-layer films

- longitudinal tear-off

- perforation

- punching

- coloring

- printing

- corona treatment for printing

Design of LDPE Films

Cooperation process

All film parameters are set after perfect acquaintance with your requirements at your operation.

Samples of the newly designed film will be delivered in sufficient quantities for thorough testing at your factory and after agreeing on all parameters, we switch to regular deliveries. During the course of our cooperation, we regularly check the quality of the films to determine your satisfaction with our deliveries and respond quickly to changing packaging requirements at your site.

Ecology

Our company practices an environmentally friendly approach and the use of modern packaging techniques to achieve savings in your operation and improve your environmental impact. In particular, we can offer films with lower thickness while maintaining quality, thereby significantly reducing the volume of material consumed. This has a positive impact not only on ecology but also on costs. From an ecological point of view, PE films are environmentally friendly and recyclable, and no harmful substances are produced when they are burned. We also offer films made from recycled material (recycled residues from production).